Laser Balast

In the completion of construction tasks related to railway equipment, one of the main setbacks that can occur is that the required amount is not available on the section to be acted upon. In these events, the execution of such planned works perceives major setbacks, since if there is not sufficient material it will not be possible to carry out the scheduled tasks. Therefore, the problem is to reach a section with a shortage of material and not being able to do so, which is why the importance of the Laser Ballast, as a system for measuring the amount of ballast using 3D vision technologies that allow to locate areas with a shortage of material in advance would expedite and improve considerably the quality of the service provided and the performance of the staff and heavy machinery assigned to these tasks.

Another objective of developing this tool is to progress in the automation of taking measurements at all the variables that affect our task scheduling, as we do not have an available technology that allows us to measure the amount of material.

It must also be assessed from an environmental point of view. The possibility of optimizing a natural resource is very important; with this tool we are able to acquaint the excess material that there may be accumulated in a vast track length, and by being able to recuperate it would significantly reduce the economic costs and transport of the raw material, as well as a cutback of environmental costs such as optimization of the use of raw materials and a reduction of the carbon footprint by reducing the amount of CO2 emitted into the atmosphere because transport from quarry to stockpile and subsequent material discharge are reduced on site.

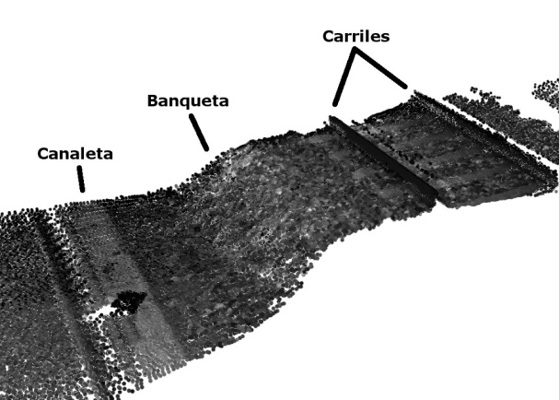

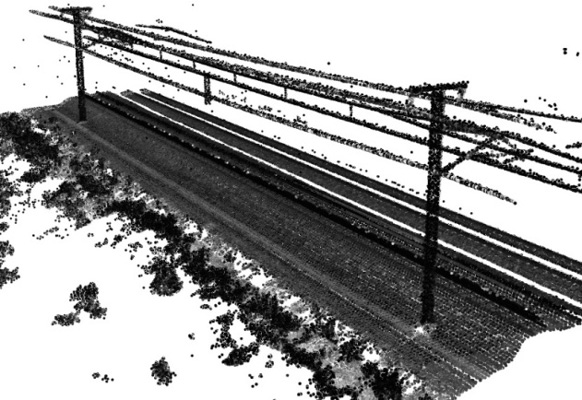

Real examples of measurements taken in real environment